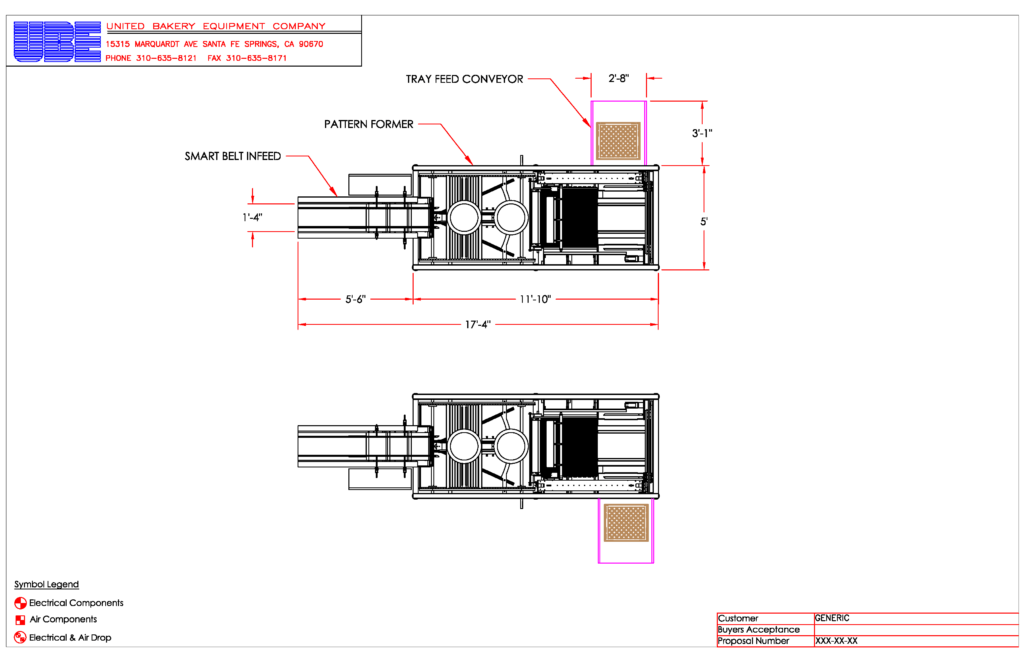

8100 Pattern Former & Tray Loader

The Model 8100 is a tray loading system and a pattern former. This machine is designed to load up to 100 loaves a minute.

UBE builds the Model 8100 Tray Loader for each customer’s particular needs. Over 1000 installations required numerous customer-driven innovations. Your machine may vary from this typical unit illustrated. UBE wants to meet with you and design your new line.

FEATURES & SPECIFICATIONS

- Stainless steel frame

- Automatically adjusts to any pattern selection

- Allen Bradley Compact Guard Logix PLC with Ethernet

- Allen Bradley Kinetix 5500 Servo Drives on dual channel Ethernet

- Smooth, Quiet Servo Drives on Orientor Disk, Product Pusher, and Window Belt

- Dual strand Intralox MTW conveyor for efficient, trouble-free operation of basket feed conveyor

- Easily accessible solenoid valves for adjustment of speed control

- KVP conveyor belts

- Uses standard plastic trays

- Allen Bradley Panel View Plus 7 Standard Terminal Touch Screen 5.7”

- Speed Up to 100 loaves/min.

- Adjustable guides for different size products

- Safety interlocked sliding guard doors for easy access to loading area

- Servo-driven orienting disk, product pusher, and loading mechanisms provide decreased vibration and noise over conventional motors