7000 TLB/WPB

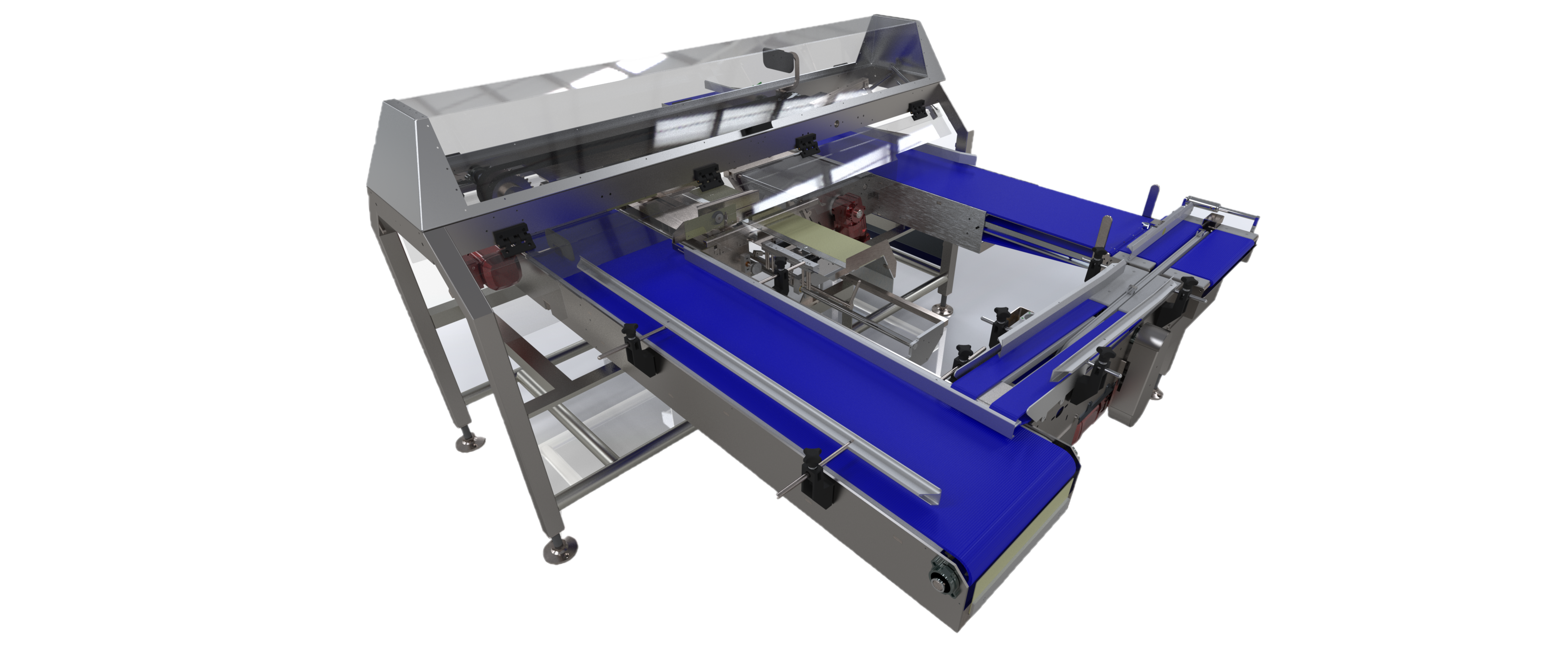

The Model 7000 TLB/WPB Bagger combines years of step by step improvements into a servo driven reciprocating bagger with fewer moving parts and increasing reliability at high speed.

UBE builds the Model 7000 Wide Product Bagger for each customer’s particular needs. Over 1000 installations required numerous customer driven innovations. Your machine may vary from this typical unit illustrated. UBE wants to meet with you and design your new line.

Sanitary by design, recipe-driven with automatic pre-operational adjustments and low maintenance ensure consistent and efficient automated high-speed bread bagging system for a variety of loaves and bag sizes. Straight-line configuration simplifies layout integration.

Small footprint reciprocating style bread bagger designed with straight-line configuration, maintenance-free, high speed pendulum scoop drive and flusher discharge conveyor for the smoothest loaf transfer available up to 75 loaves per minute.

Automated bread bagging system ensures consistent and versatile high-speed production for a variety of loaves and bag sizes. Straight-line configuration simplify layout integration.

FEATURES & SPECIFICATIONS

- Designed to allow bread not intended for double bagging to “pass through” onto the palletizing station

- Products are bagged as a permanent location or it may also be portable

- Bag Closing may be by a twist tie, Plastic tab, or heat sealer

- Typically set up for a fixed speed of 30 packages per minute, apply to factory for variable speed option

- Designed with sanitation in mind, stainless 304-4 guarding, and corrosion resistant stainless steel sealed fully welded spaced off-panel mounting eliminate hollow spaces and frame perforation.

- Safety guarded access doors complying with CSA and OSHA regulations

- Programmable scoop height infeed phase change and scoop dropout timing

- AB Panel View 600 plus color touch screen ethernet communication

- Patented flusher discharge conveyor ensures the smoothest loaf transfer while preventing loaf disruption often caused by conventional flusher bars. Consistent embedded cam follower reduces top scoop vibration

- Suitable for use at the discharge of your bread bagger as a permanent location or it may also be portable

- Products are bagged with the “tails in” or “tails out” to suit buyers marketing and layout needs

- Design to be simple and easy to use, automatic or hand fed, portable or stationary

- Machine can accommodate packaging depending on layout

- Reduced horizontal surfaces, great internal accesses, removable crumb collection slides, welded wire support rod, infeed and discharge conveyor decks for timely and effective cleaning meeting high food safety.

- Finger safe conveyor design with patent pending flights on both conveyors allows full access of loaf-handling eliminating tunnel guarding reducing maintenance. Skip loaf function allows reintroducing sliced loaf or closing bagged loaf without stopping the bagger operation

- Servo drives replace all cams and provide independent servo drives

- Pendulum-style scoop drive delivers low vibration and optimal operation from 35 to 75 LPM. Top scoop level bag pick-up and release motion ensures consistent bagging performance

- UBE safety standard includes safety guarded access doors and basic tunnel conveyor guarding complying with CSA and OSHA regulations