75-2 Bread Bagger

The Model 75-2 Servo Bread Bagger combines years of step-by-step improvements into a servo driven reciprocating bagger with fewer moving parts and increasing reliability at high speed.

UBE builds the Model 75-2 Servo Bread Bagger for each customer’s particular needs. Over 1000 installations required numerous customer driven innovations. Your machine may vary from this typical unit illustrated. UBE wants to meet with you and design your new line.

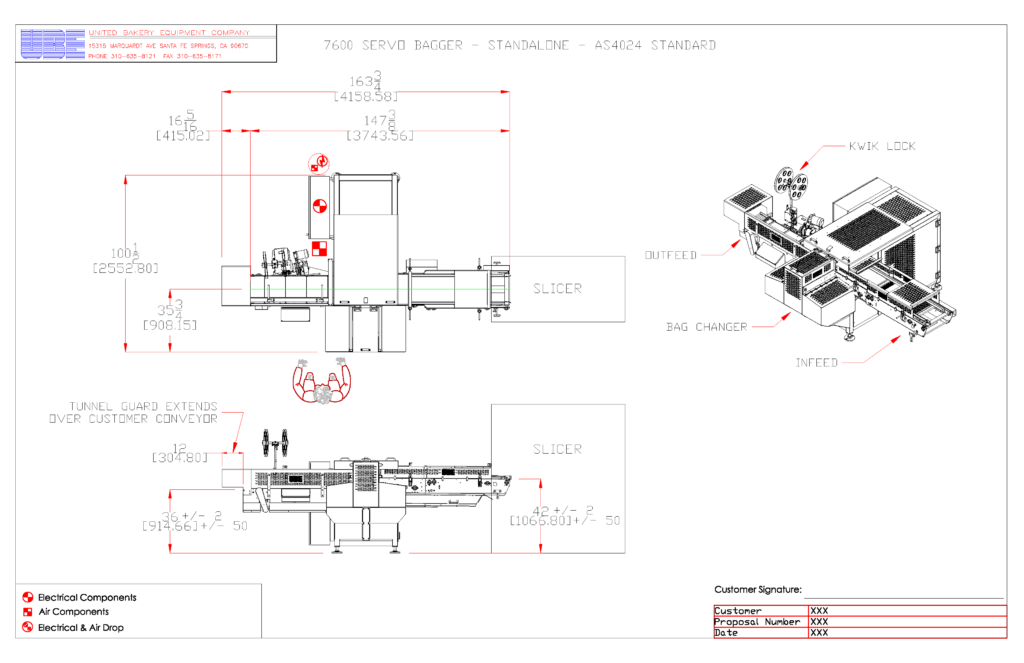

Small footprint reciprocating style bread bagger designed with straight-line configuration, maintenance-free, high speed pendulum scoop drive and flusher discharge conveyor for the smoothest loaf transfer available up to 75 loaves per minute.

Automated bread bagging system ensures consistent and versatile high-speed production for a variety of loaves and bag sizes. Straight-line configuration simplify layout integration.

Sanitary by design, recipe-driven with automatic pre-operational adjustments and low maintenance ensure consistent and efficient automated high-speed bread bagging system for a variety of loaves and bag sizes. Straight-line configuration simplifies layout integration.

FEATURES & SPECIFICATIONS

- Bagging Speed up to 70 Loaves Per Minute

- Air Requirements: 6 CFM, 90 PSI - Dry filtered

- Maximum Product Length 16"

- Allen Bradley Control Logix and Kinetix Servo Frives on a Sercos network

- Automatic Dual Wicket Change System Allows Wicket Change Without Stopping the Bagger Operation

- BISSC Approved

- Designed With Sanitation In Mind, Fully Welded Spaced Off-Panel Mounting, No Hollow Spaces Or Frame Perforations, Reduced Horizontal Surfaces And Great Internal Accesses

- Finger-Safe Conveyor Design With Patent Pending Flights on Both Conveyors Allows Full Access of Loaf-Handling Eliminating Tunnel Guarding, Reducing Maintenance

- Infeed Transfer Rollers Designed for Improved Product Transfer

- Pendulum-Style Scoop Drive Delivers Low Vibration and Optimal Operation from 35 to 70 Loaves Per Minute

- Protective Bag Over Scoop System Reduces Package Damage Caused by Hard Crust Loaves

- Servo Drive System with Strong Gearbox for High-Speed Production

- Servo Drives Replace All Cams and Provide Independent Servo Drives

- Simple Pivot Arm Motion Replaces Scoop Slide

- Stainless Steel Frame

- Top and Bottom Air Jets with Misses Bag Detection

- Optional AS4024 Approval

- Optional Automatically Synchronized Speed Control Between Multiple Machines or for Entire Packaging Room

- Optional CE Approval

- Optional CUL Approval

- Optional UL Approval

- Slice thickness range 3/8” to 5/8” [9.5 to 15.9mm] standard

- Electrical Options: 208/230/380/460 V - 3 Phase, 50/60 Hz

- Minimum Product Width 6"

- Allen Bradley Touch Screen

- Available in Metric Construction

- Category 3 Safety Compliant Guarding with Coded Magnetic Door Switches

- Double Loaf Eliminating Conveyor on Infeed Allows Continuous Operation and Seamless Operation While Machine Is Double Fed

- Infeed Conveyor Phase Variator Synchronizes Infeed Flights to Scoop in Motion for Maximum Flexibility with Loaf Variety, Providing a Full 360˚ Range of Position Control

- Patented Belted Flusher Discharge Conveyor Ensures the Smoothest Loaf Transfer While Preventing Loaf Disruption Often Caused by Conventional Flusher Bars

- Programmable Scoop Height, Infeed Phase Change, and Scoop Dropout Timing

- Rapid Scoop Removal for Efficient Product Changeover

- Servo Driven Top Scoop

- Servo-Driven Conveyors, Recipe Setup Pre-Programmed Controlling Different Product Parameters

- Skip Loaf Function Allows for Manual Placement of a Bagged Loaf for Closing Without Stopping Equipment

- The Pendulum System Eliminates Costly Maintenance of Scoop Drive Gearboxes

- Top Scoop Level Bag Pick-Up and Release Motion Ensures Consistent Bagging Performance

- Optional Automatic Guide Rails

- Optional Bag Closure Unit and Printer: KWIK LOK, Burford, WE SEAL

- Optional CSA Approval

- Optional Stainless Steel Electrical Enclosure IP66 (Nema 4) Rated